Introduction: Why the Side-opening Folding Storage Box Matters

Today, in fast-moving logistics, storage, and home organization, the design of the container for storage still has a significant impact. Many alternatives have been proposed, and the side-closing storage box has become a popular and efficient solution to a variety of problems in the storage industry- from retail, e-commerce fulfillment, and automotive parts to residential storage and seasonal storage.

The combination of a foldable ( collapsible ) structure and a door or hatch that opens from the side instead of only the top has a functional advantage: easier access, more ergonomic design, greater stacking, and more flexible configuration. As organizations seek to maximize space, increase productivity, and reduce costs, understanding the exact nature of a side-opening storage box that is folded is crucial. This guide discusses the various definitions, design attributes, materials, applications, criteria for specialization, and market trends.

Defining the Side-opening Folding Storage Box

In order to accurately describe and measure, we must first define and compare the most important terms.

Side-opening Folding Storage Box is the name given to a container that has a door, flange, or panel on one (or more) of the vertical sides of the box, instead of a single-lifting lid. This design allows access to the box when it’s stacked, stored, or placed in confined spaces. For instance, a manufacturer describes their “folding storage box with lid and a side-open door” as being quick to access and preventing dust.

Folding/Collapsible denotes that the box can be compacted into a lower height (and sometimes width/depth) when not in use, which enables savings in flat storage and transportation. For example, a 50 L large capacity box that flaps down to about 10 cm high for storage.

The storage box in this context is a container that is intended to store, arrange, or transport items; it is often stackable, durable, reusable, and possibly modular.

Combining it: a side-accessing folding storage box is a container that possesses side access, is collapsible, and has a storage function. Many manufacturers focus on features like large capacity, high load-bearing, lightweight plastic, stacking ability, and space-saving when folded.

Core Design Features & Functional Advantages

What differentiates this style of box from a standard storage bin that only has a lid? Let’s discuss the benefits and features of our product.

-

Side Access Doors or Panels

The panel that opens on the side provides an efficient means of access to the contents without having to take the box off a stack or move other boxes.

Advantages:

- Increased accessibility to shelving units, pallet racking, or file storage scenarios.

- Faster item recovery- reducing the amount of time spent retrieving items.

- Minimizes the disturbance caused by the other boxes in the stack.

- Good for small lanes or when boxes are placed one above another for storage.

-

Folding mechanism / Collapsibility

When it’s not in use or has been empty, the box can be folded into a small volume that saves space.

Advantages:

- Lower costs of transport and storage associated with empty boxes.

- Minimized the footprint of the warehouse in the absence of deployment.

- Easy access to the return logistics for reusable containers.

-

Stackability and Modularity

Side-opening boxes that fold in the middle often have features that make it safe to stack–interlacing spheres, grooves, and additional structure. The same methodology: “overlapping nodules promote safe storage… their shape resembles a grooved design that increases strength”

Advantages:

- Effective vertical storage in stores.

- The capacity to combine different sizes in modular structures.

- Support for heavy boxes that act as furniture or seats (in rare instances).

-

Substance and Conclusion

Many side-closing boxes that are decorated with plastic are made of polypropylene (PP) or another durable plastic, often BPA-free, DEHP-free, and heavy metal-free. Example: plastic that is durable, non-toxic, and virgin; this plastic is resistant to impact.

Advantages:

- Lightweight yet powerful.

- Adept at repeated cycles of folding and unfolding.

- Resistance to corrosion, moisture, and dust—perfect for both residential and commercial applications.

-

Multiple Use/Permacultivo

Some boxes that fold have dual functions; for example, the lid can function as a bench or table when combined with it. Example: The “double-opening top design… can be employed as a simple stand.”

Advantages:

- Home, retail, storage, events.

- Extra value for customers- additional storage and furniture.

- Difference for high-end markets.

Materials, Construction & Manufacturing Considerations

For those who make B2B decisions, the quality of the material and the construction of the storage box define its performance, cost, and lifespan.

-

Different Kinds of Substances

Plastic (Plastic Polypropylene – PP): The most common substance. Example: The plastic PP with the capacity to hold loads is indicated (e.g., 20 kg of boxes, 100 kg of tops).

Metal Supports: Some examples include steel struts or flaps that are intended to increase the stacking force. Example: “+ steel bar to augment the stackable storage box.”

Wooden or Composite Lid: Some variants utilize wood as the lid/top panel; this dual function is accomplished by placing a bench or table beneath the lid.

-

Structural Design and Load Indication

Specifications like the 50 L capacity, 20 kg of internal weight, and 100 kg of top weight (on a bench) appear. Example: Product: Material: PP; Box capacity: 20kg; Top capacity: 100kg.

Key factors that design the key:

The thickness of the wall in the box,

Design of the Reinforcement Ribs or the Tenon’s design,

The quality of the hinges or side-opening panel,

Stacking bets or mutual exclusions.

-

Manufacturing & Fold-down Mechanism

Successful folding is dependent on precise molding, hinge design, and tolerances. Example: The box above has a height of 300 mm and a volume of 100 mm. This type of mechanism is associated with quality.

For the largest volume of production, providers should indicate the daily capacity, lead-time (30-45 days for custom orders), and MOQ. Example: “Lead time: 30-45 days based on the order volume.”

-

Customization and OEM features

Many providers emphasize custom colors, logos, laser printing, extra features, or wooden tops. Example: Custom colors…

For B2B supply chains, customization allows for brand identification, a retail presence, or corporate acquisition.

Specification Checklist: What to Look for When Sourcing

Below is a specification checklist that procurement or product development teams should consider when sourcing a side-opening folding storage box.

| Specification Item | Why It Matters | Target Specification or Consideration |

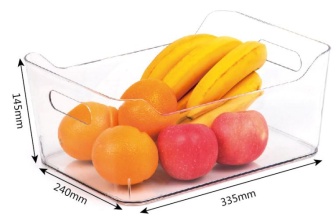

| Capacity (Litres/Dimensions) | Ensure fit for intended content | e.g., 45–50 L for general use |

| Fold-down height | Determines storage footprint when collapsed | e.g., <110 mm when folded |

| Side-opening door dimension/design | Access ease, ergonomics | Wide access, dust-tight panel |

| Material and safety certification | Durability + regulatory compliance | Virgin PP, BPA/DEHP free, heavy-metal free |

| Load ratings (internal & stacking) | Safety and functional load bearing | 20 kg internal, 100 kg top load for bench use |

| Stackability & interlock features | Warehouse efficiency & safety | Interlocking nodules, groove design |

| Customisation options | Branding & retail differentiation | Custom colours, logos, accessories |

| Lead time / MOQ for customised orders | Fit with supply chain timing | 30–45 days lead time, MOQ stated |

| Finish and mechanism durability | Ensures longevity and repeat use | Durable hinge, smooth fold/unfold cycles |

| Multi-purpose function | Added value to buyer/consumer | Lid doubles as table, optional casters |

Using this table as part of your sourcing specification helps ensure you receive a product fit for purpose rather than generic storage bins.

Applications and Use-Case Scenarios

Side-closing storage boxes that are foldable have a variety of uses in multiple industries:

-

Warehousing and Transportation

In distribution centers and online retail, side-access increases the efficiency of retrievals, particularly when containers are stacked. Recognisable boxes diminish the cost of logistics returns. Example: the specifications state that, even when multiple storage boxes are placed on top of each other, it is easy to collect the items without moving.

Use-cases include the storage of parts, the returnable totes, and modular stacking in the aisles.

-

Retail Offices and Inventory Stations

Retailers need storage that is flexible in terms of space, seasonal items, and returns. A plastic box that folds down provides a ready-made, stackable storage option with side-opening access that facilitates faster inventory management.

-

Home/ Residential Use

The same ideas of product design apply to domestic settings: underserved storage, organized storage, and seasonal storage. Example: “Foldable large capacity and high capacity… Lightweight plastic material, versatile and space-saving.”

Features like the lid’s dual function as a table are popular with home decorators.

-

Outdoor, Backpacking, and Traveling

Some boxes are intended for use in car cabs, camps, or outdoors, where the collapsibility and accessibility of the side are important (e.g., placing in a car trunk and retrieving items from the side). Example: The 36 L Foldable Storage Box with a side door that is marketed for its large capacity and side-opening design.

-

Businesses, events, and temporary storage.

For events that require pop-up storage, displays, or mobile shopping, these boxes have quick-deploy capabilities, a stackable design, and a later collapse that is transport-friendly.

Advantages and Considerations – A Balanced View

Understanding the benefits as well as the potential trade-offs is crucial to informed decision-making.

-

Advantages

Increased access via the side door leads to a quicker return, more efficient handling.

Space-saving while folded; decreased footprint for additional units.

Flexibility: can be used as a table or as a stand, it’s versatile.

Durable materials and load ratings are appropriate for industrial use.

Ideal for environments with a lot of dynamic storage space, the configuration of boxes is frequently altered.

-

Concerns / Future Limitations

The mechanism for side-opening may increase the cost and complexity compared to basic lids-only boxes.

Mechanical folding requires high-quality molds that are expensive; cheaper units may fail over time or develop issues with the hinge.

The capacity of a stack to bear loads is primarily derived from the design of the box and the interlocks–poor design will lead to a safety risk.

The flat height that is folded may still have a significant impact on large quantities; the savings associated with transport are variable.

For specific substances (e.g., heavier parts or liquids), access through the side may necessitate the entire removal of the stack. On rare occasions, top-opening is still beneficial.

Market Trends & Future Outlook

What is causing the growth and evolution of side-closing storage boxes that are open on the top? Here are the most important developments:

Increased demand for modular, collapsible storage that is driven by urban living, smaller homes, micro-warehouses, and multi-purpose areas.

E-commerce and automated fulfillment: Side-opening containers are ideal for quick access in stacked racks or automated retrieval systems.

Customizable designs and lifestyle branding: storage boxes that can be used as both furniture and decoration– versions that have a wooden lid, or decorative colors.

Sustainability: materials that can be repeatedly used, folded into a flat configuration for return logistics, and designs that enhance the life cycle.

Integration with smart logistics: sensors, labeling systems, crates that can be folded, tracking inventory, and circular economy use of foldable containers.

Global supply chain efficiency: large-volume, flat-packed returnable crates diminish the amount of space needed for storage and shipping when they’re empty.

Reports from leading suppliers that specialize in industry show that multiple-purpose “side-opening storage boxes with a folding” design are being utilized as the foundational components of smart warehouse design and domestic organization. For instance, one supplier promotes their product as “space-saving… side-door… stackable… modular design” that focuses on both business-to-consumer and consumer-to-business appeal.

Summary and Final Thoughts

The side-closing storage box that is opened in the middle represents a meeting of design innovation, practical application, and efficiency in the supply chain. For both manufacturers and retailers, it provides a powerful solution: quick access through side-closing doors, foldability to save space when not in use, stacking and modularity to optimize environments for space, and materials that are built to withstand industrial demands. Whether your system is for storage in the warehouse, retail back-office, organization at home, or an event logistics system, understanding the benefits, composition, and functional aspects of your application will allow you to choose, procure, and deploy the appropriate container.

When designing these boxes, remember the important criteria: capacity, fold-down size, door access, load ratings, material compliance, stackability, customization options, and lead time. Pay attention to quality: Ineffective hinge design or poor plastic may lead to early failure or increased costs. The market is reportedly moving towards modular, versatile solutions and side-opening boxes that are well-suited to addressing evolving demands.

Ultimatum: if your storage dilemma involves stacked access, foldable footprint, industrial efficiency, and ergonomics, then the side-opening folding storage box is worth serious consideration. By combining functionality, ergonomics, and sustainability, you can transform what appears to be a simple container into a strategic resource for effective storage, handling, and space utilization.